This isn’t a post about a new project so some might find it boring. If so, feel free to skip reading it!

It must be said that I am NOT an expert on sewing, sewing machine issues, or stitching issues generally, this is just a list of what has solved problems for me. It was collated during many hours troubleshooting the foibles of my own machine, a Janome DKS100. I watched countless YouTube videos, browsed dozens of sewing blogs and avidly read the forums on Sewing Pattern Review. I realised it would be be a useful reminder for me to have all this information in one place, but if it also helps someone else then I’d be really pleased. It can be very frustrating to suddenly come up against weird issues that frustrate your sewing experience.

Apart from its inability to handle thick fabric (jeans hems? No chance!) the biggest issues with my DKS100 have been with buttonholes, the strange solution to which is detailed at the bottom of this post. Without further ado, here is my list of how I troubleshoot stitching issues, with the most important suggestions (in my experience) first:

- The first rule of troubleshooting, learned from many years’ experience in my working life: never change more than one thing at a time or you’ll never be sure what the fix was. Until the next time the problem occurs, of course, when you’ll be wiser!

- RTFM. Sorry if that offends but it’s essential to properly read the manufacturer’s guide to the machine and make sure you’ve followed the instructions to the letter in terms of threading etc. Undoubtedly some of my frustrations have been self-generated because I haven’t done this, or haven’t done it thoroughly enough.

- Bobbin

- brand: my Janome only behaves itself with Janome bobbins so I have just started marking them with a red dot in permanent marker to ensure I don’t get them mixed up with to those for my standby Necchi machine, which isn’t so picky.

- running low on thread. My machine starts skipping stitches if the bobbin thread is close to the end. Or even not so close (again, see below).

- ensure it’s wound properly. My machine is finicky if a bobbin hasn’t been wound properly, and it isn’t always good at winding them.

- In the past, if I was short of bobbins, I was guilty of winding new thread onto a bobbin which already contains thread but I read that’s a big no-no so I haven’t done that for ages.

- Needles

- my machine doesn’t like cheap needles so I only use Schmetz

- make sure you’re using the right needle for the fabric and task. Obvious, really, but sometimes the obvious needs to be stated

- replace them frequently. If you’re unsure about how worn a needle is: replace it

- if my machine starts skipping stitches and I’ve already eliminated bobbin issues, I replace the needle even if it’s new. It could be faulty (rare with Schmetz) and they’re cheaper than buying a new machine when you’re ready to throw it out of the window!

- Thread – my Janome has expensive taste, I simply cannot use cheap thread. I tried thread from Lidl once and ended up giving it away. Gutermann mostly seems to work very well so I stick with that.

- If you’re having issues with buttonholes on uneven fabric, try using a stabiliser plate if your machine comes with one.

- Unless yours is a mechanical machine, remember these are computers: if all else fails try shutting the machine down, unplugging it from the mains, waiting a couple of minutes and plugging it back in again. This has solved issues for me on several occasions.

Some people may wonder why I haven’t mentioned tension issues but – and I hope I’m not tempting fate - that’s never been an issue with my machine.

So, back to those buttonholes, which are particularly troublesome on my DKS100. In fact, this post was prompted by a recurrence of buttonhole issues which I thought I had found the strange answer to several years ago. The rather blurry picture below shows the fourth buttonhole after my machine had stitched three previous ones perfectly:

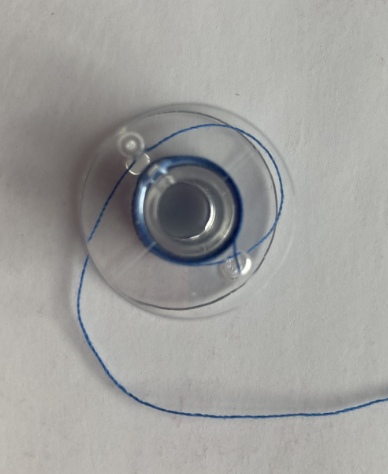

I ignored all my own advice and wasted a couple of hours looking at replacement machines but, in the end, this was the culprit: the bobbin, which was starting to run low although it certainly wasn’t at the point of running out:

And so for the strange case of the dodgy buttonholes: I only became brave enough to try buttonholes shortly before the warranty on my machine ran out – another mistake I won’t ever make again. The machine would stitch a test buttonhole and maybe 3 or 4 perfectly, then start skipping stitches. I returned it to Janome UK (after a lot of reluctance on their part) but they returned it weeks later “no fault found”.

Yet I still couldn’t get all the buttonholes in a project completed without it failing on the fourth or fifth one. I tried all the above and there was no improvement. I was so frustrated I was ready to replace my machine when I decided to try using it without the foot pedal. Every buttonhole stitched perfectly! I presume that, on a bench in the workshop at Janome, they wouldn’t have been using the foot pedal. I now routinely unplug it before I sew buttonholes and, until this week, my DKS100 has stitched them perfectly every time.

The moral of the tale? Remember that these ARE computers, with software glitches, and they can behave very oddly sometimes. I’ve worked in IT for nearly 40 years so that’s something I do have lots of experience of!